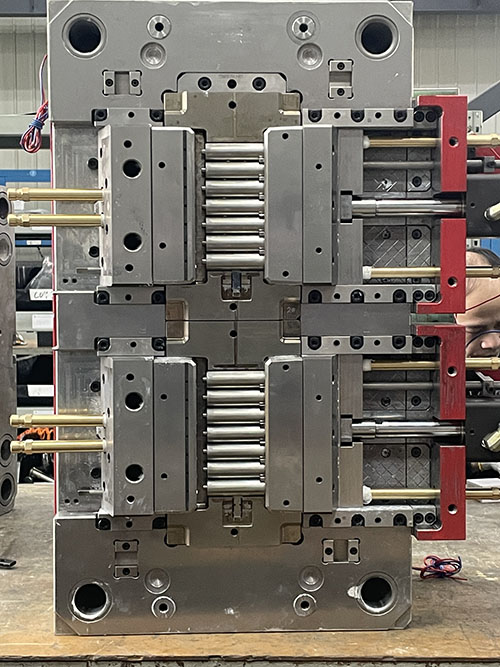

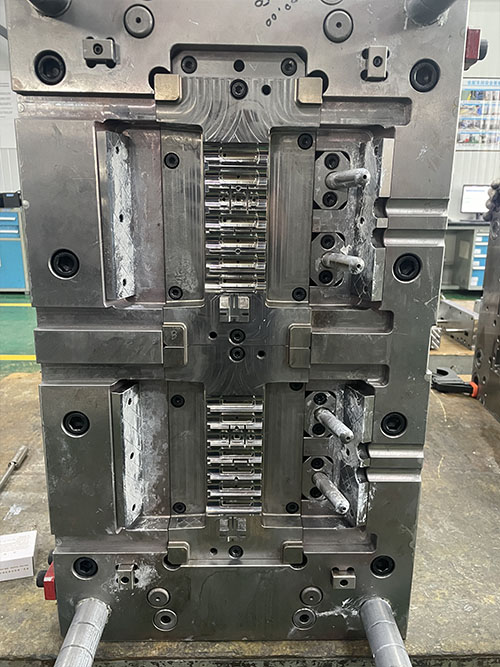

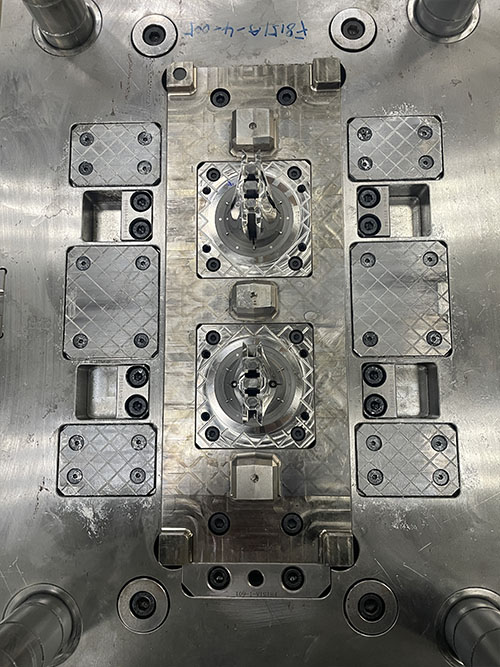

INJECTION MOLD

MOLD ANALYSIS

Evaluation of existing tooling for ways of improving quality, repeatability, and minimizing scrap and injection cycle times.

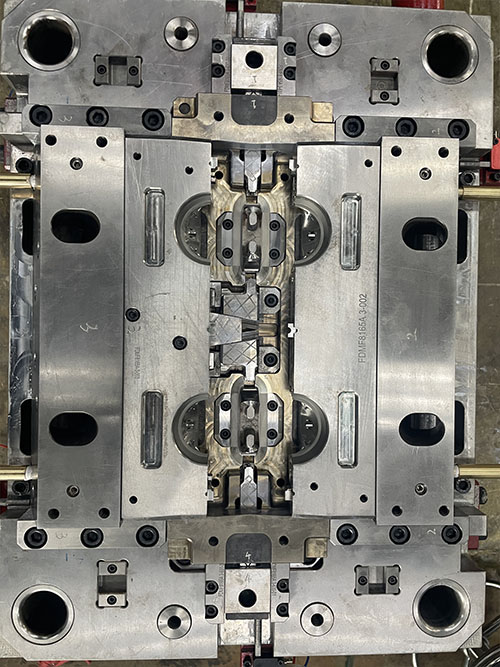

PROTOTYPE MOLD TESTING

During initial runs, evaluate those areas that may create some issues downstream with production tooling, Working with the engineering team to make those needed changes at the prototype stage.

MATERIAL TESTING

Finding possible or similar material alternatives for cost saving and to ensure a second material source exists in the event there are shortages of the primary resin.

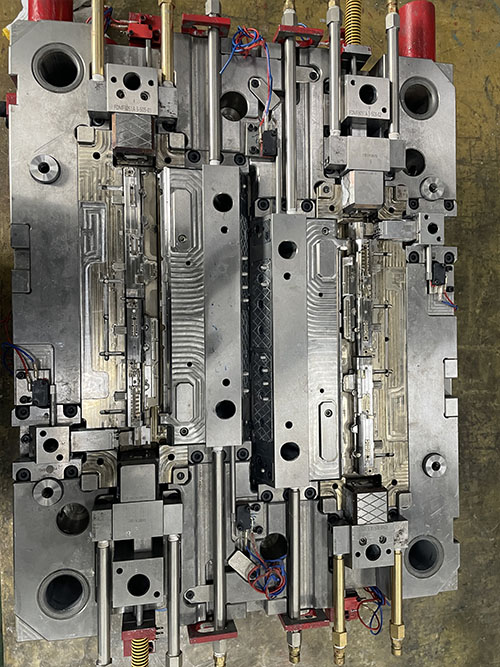

PROCESS OPTIMIZATION

By using scientific methods in creating the optimum process, we can ensure that a robust process has been created, eliminating variations in part geometry, quality, and integrity.

SECONDARY OPERATIONS TO THE MOLDED PART

We offer post-molding services such as ultrasonic welding, pad printing, and silk screening, along with the assembly of molded and non-molded components.

CUSTOM QUALITY INSPECTION PROGRAMS

We work with our customers to create a Quality Inspection Package from 1st article inspection through finished goods inspection based on the critical aspects of each part we produce.