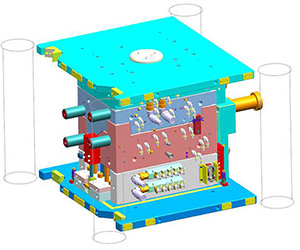

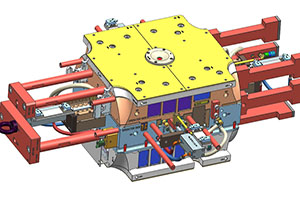

MOLD DESIGN

Design and engineering

RFQ FOR TOOL DESIGN/DFM CONNECT WITH EMAIL ADDRESS: [email protected]

Successful tooling projects start with creating a part design that meets the customer’s specifications and requirements. At HaoMold, our engineering team can incorporate the necessary features conducive to good manufacturing processes for plastic injection molding and die casting mold, performing this task professionally and confidentially, Using state of the 2D/3D software, we create not only the part design but the moulding design as well to achieve a more cost-effective mold. After the approval of the final drawings, the manufacturing process is initiated. As a company with advanced mold making capabilities, we give our customers the knowledge and confidence needed to assure success during the initial launch. Whether it is a prototype project or multi-cavities production mold, we are good at it.

Evaluation

The product structure analysis includes appearance requirements, shrinkage, deformation, undercut, draft angle, part line, injection gate, etc.

The mold structure analysis includes: parting surface, gate type and location, slider, lifter, insertcooling, ejection, part-taking method, appearance

treatment, mold strength, and life, etc.

Our design Software:

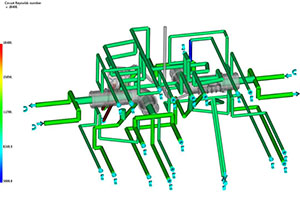

AutoCAD *SolidWorks *Pro/Engineer *Unigraphics *MoldFlow

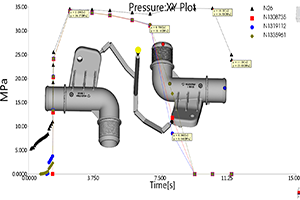

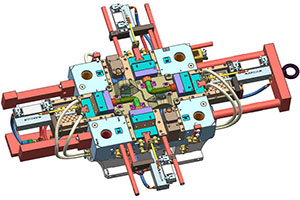

The case of moldflow photos

We can accept and convert below document formats:

2D: DWG, DXF, PDF 3D: X_t,IGES, STP.PRT. STL

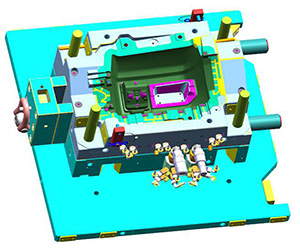

EG. The pipe drawing

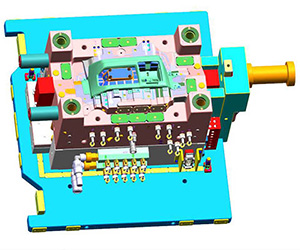

EG. Centre Console Small Lower LHD Auto